AIRPOXY SPECIFIC OBJECTIVES

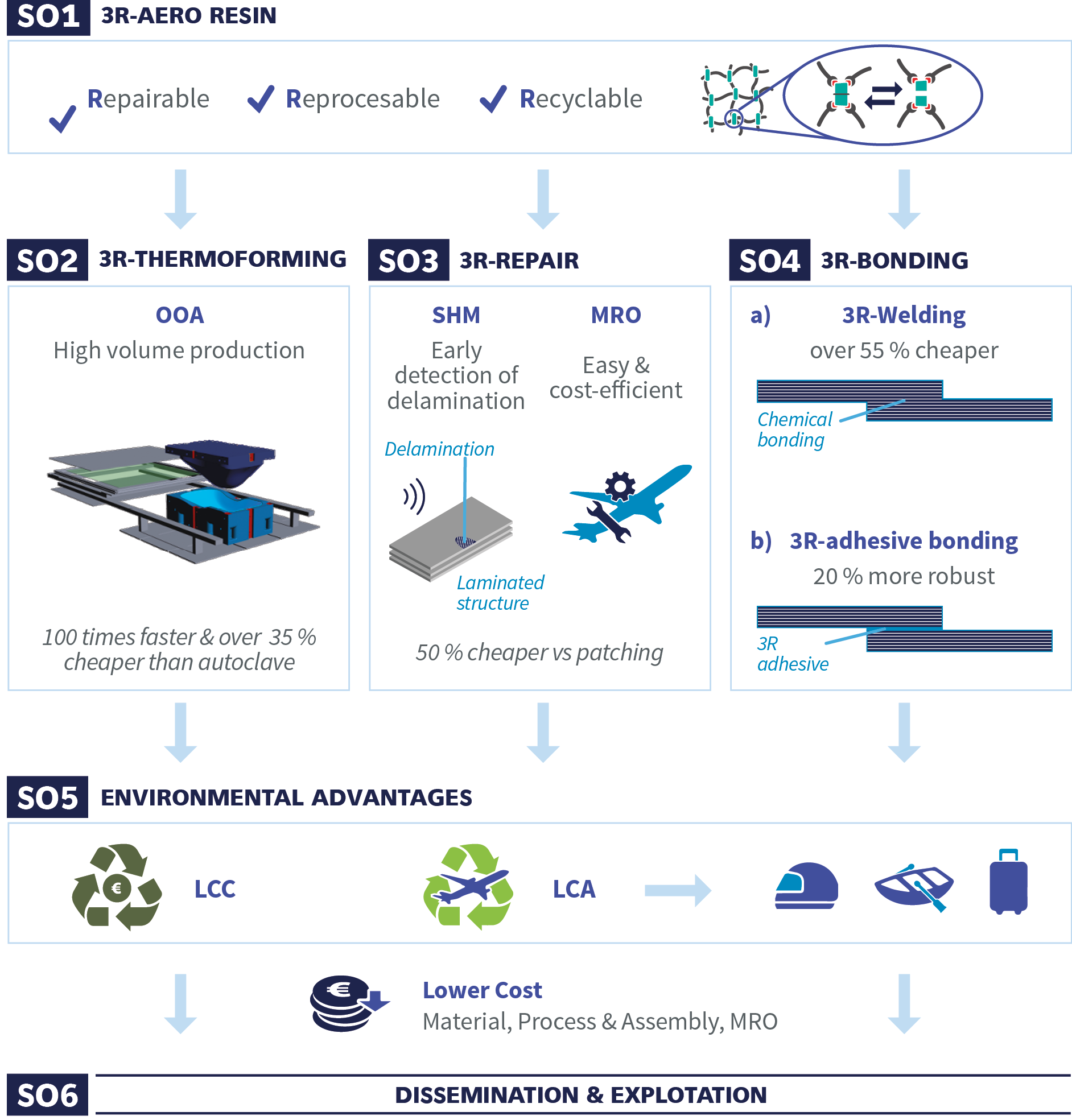

To achieve the global aim of reducing the production and maintenance costs of composite parts in the aeronautic sector, the AIRPOXY partners have defined six main specific objectives (SO) as illustrated in the image below. The SOs are described in more detail under the image.

SO1: Bring the Technology Readiness Level (TRL) of a new family of 3R thermoset resins based on dynamic bonds for aircraft applications from TRL3 (proof of concept) to TRL 5 (validation in industrial environment). This will be achieved by the development of a high-performance 3R resin formulation which meets the specific processing and performance requirements of aeronautic sector related to viscosity, Tg and mechanical properties.

SO2: Reduce the costs of manufacturing thermoset Carbon Compositee parts by over 35% as compared to autoclave manufacturing by developing a new processing technology for thermosets, 3R- Thermoforming technology, which is 100 times faster with higher levels of automation as compared to autoclave manufacturing.

SO3: Reduce the current costs of MRO associated to the reparation or replacement of thermoset CC parts by 50%. This will be achieved through the combination of early detection and quantification of delaminations and resin microcracks damages by applied SHM techniques for prompt repair and the development of a new 3R-Repair technology that is 55% faster than current patch techniques.

SO4: Reduce the costs of current adhesive bonding of thermoset CC parts by over 50% and increase of their robustness by 20%. This will be achieved by the development of a new bonding process called 3R-Bondin

SO5: Quantify the environmental advantages of the recyclability of the 3R CC parts at the end of life (EOL) versus traditional Carbon Composite parts using Life Cycle Assessment (LCA) & Life Cycle Cost (LCC) methodologies.

SO6: Ensure proper dissemination and future exploitation of the developed 3R technologies to reach TRL9 (system proven in operational environment) after the end of the project